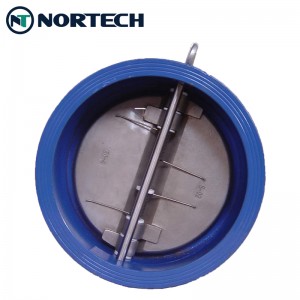

Check valve: Check valve is also known as one-way valve or check valve, its function is to prevent the medium in the pipeline Backflow. The bottom valve of the pump to close the water also belongs to the non-return valve category. The valve that opens or closes on its own by the flow and force of the medium to prevent the medium from flowing back is called a check valve. Check valves belong to the category of automatic valves. Check valves are mainly used in pipelines where the medium flows in one direction, and only allow the medium to flow in one direction to prevent accidents. According to the structure of the check valve, it can be divided into three types: lift check valve, swing check valve and butterfly check valve. Lift check valves can be divided into two types: vertical check valves and horizontal check valves. Swing check valves are divided into three types: single-leaf check valve, double-acting check valve and multi-leaf check valve. The butterfly check valve is a straight-through check valve. The above-mentioned check valves can be divided into three types in connection form: threaded check valve, flanged check valve and welded check valve.

The installation of the check valve should pay attention to the following: Do not make the check valve bear weight in the pipeline, and the large check valve should be independently supported so that it is not affected by the pressure generated by the piping system.

When installing, pay attention to the direction of medium flow should be consistent with the direction of the arrow voted by the valve body.

The lift-type vertical check valve should be installed on the vertical pipeline. The lift-type horizontal flap check valve should be installed on the horizontal pipeline.

Main performance parameters of check valve: Nominal pressure or pressure level: PN1.0-16.0MPa, ANSI CLASS1 50-900, JIS 10-20K, nominal diameter or caliber: DN15-900.

NPS 1/4-36, connection method: flange, butt welding, thread, socket welding, etc., applicable temperature: -196℃-540℃, valve body material: WCB.

ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8 (304), CF3 (3041), CF8M (316), CF3M (316L), Ti, choose different materials, check valves can be used for water, steam, oil, nitric acid, acetic acid, oxidation Sexual media, urea and other media.

Post time: Jun-17-2021