Check valve is to rely on the flow of the medium itself and automatically open and close valve disc, used to prevent the media flow back valve, also known as check valve, one-way valve, countercurrent valve, and back pressure valve.

Check valve action

Check valve is a kind of automatic valve, its main function is to prevent media backflow, prevent pump and drive motor reverse, as well as the discharge of container medium. Check valves can also be used to supply lines in which pressure may rise to exceed system pressure in the auxiliary system.

Classification of check valves

Check valves can be divided according to their structure and installation:

1. Swing check valve

Swing check valve disc disc, rotating around the valve seat channel axis for rotary movement, because the valve channel into a linear flow, flow resistance is small than the lifting check valve, suitable for low flow velocity and flow not often change of large diameter occasions, but not for pulsating flow, its sealing performance is not as good as lifting. Swing check valve is divided into single, double and half three types, these three forms are mainly divided according to the valve diameter, the purpose is to prevent the medium to stop flowing or reverse flow, weaken the hydraulic impact.

2. Lift check valve

Disc along the vertical center line of the valve body slide check valve, lifting check valve can only be installed in horizontal pipeline, in the high pressure small diameter check valve disc can be used in the ball. Lift check valve body shape and globe valve (can be used with globe valve), so its fluid resistance coefficient is larger. The structure is similar to the globe valve, and the valve body and disc are the same as the globe valve. The upper part of the valve disc and the lower part of the valve cover are processed with a guide sleeve, the valve disc guide sheet can be free to rise and fall in the valve lamp guide sheet, when the medium downstream, the valve disc by the medium thrust open, when the medium stop flow, the valve disc by vertical landing on the seat, prevent the medium countercurrent effect. Straight-through lifting check valve medium inlet and outlet channel direction and valve seat channel direction vertical; Vertical lift check valve, its medium inlet and outlet channel direction and seat channel direction is the same, the flow resistance is smaller than straight-through.

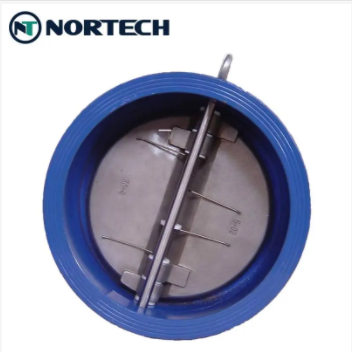

3. Disc check valve

A check valve in which the disc rotates around the pin in the seat. Disc check valve structure is simple, can only be installed in horizontal pipeline, poor sealing.

4. Pipe check valve

Valve where the disc slides along the centerline of the body. Pipe check valve is a new valve, its small volume, light weight, good processing technology, is one of the development direction of check valve. But the fluid resistance coefficient is slightly larger than swing check valves.

5. Pressure check valve

This valve is used for boiler feed water and steam cut off valve, it has lifting check valve and globe valve or Angle valve integrated function.

Nortech is one of the leading industrial valve manufacturers in China with quality certification ISO9001.

Major products: Butterfly Valve, Ball Valve,Gate Valve, Check Valve, Globe Vavlve,Y-Strainers, Electric Acurator , Pneumatic Acurators .

Post time: Oct-18-2021