High Performance Double eccentric butterfly valve lug type China factory

What isDouble eccentric butterfly valve lug type ?

Double eccentric butterfly valve lug type is an innovative double offset design product with advanced world leading technology. This butterfly valve has a unique structure with ultra reliable sealing performance, wide working conditions and low operation torque.

The low friction PTFE bearings ensure low operating torques and the protected shaft ends secure durability since there are no uncoated ductile iron surfaces exposed to the media.

it allows the disc to move off the seat reducing running torque and seat wear,it's a big advantage compared to the concentric butterfly valves.

The tension on the disc is released after a few degrees of opening which minimises wear of the disc seal. Furthermore, the design minimises the compression of the sealing which ensures low operating torques.

Main features of Double eccentric butterfly valve lug type

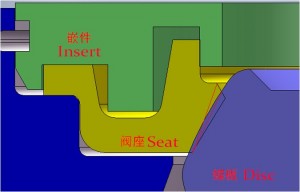

Sealing machnism of Double eccentric butterfly valve lug type

Main features of NORTECH Double eccentric butterfly valve lug type

- it's easy to replace the seat by removing the insert,convenient for maintenance.

- There is a safe blow-out structure at the top of the stem

- Excellent adjustment characteristics

- Fire proof design

Sealing machnism of Double eccentric butterfly valve lug type

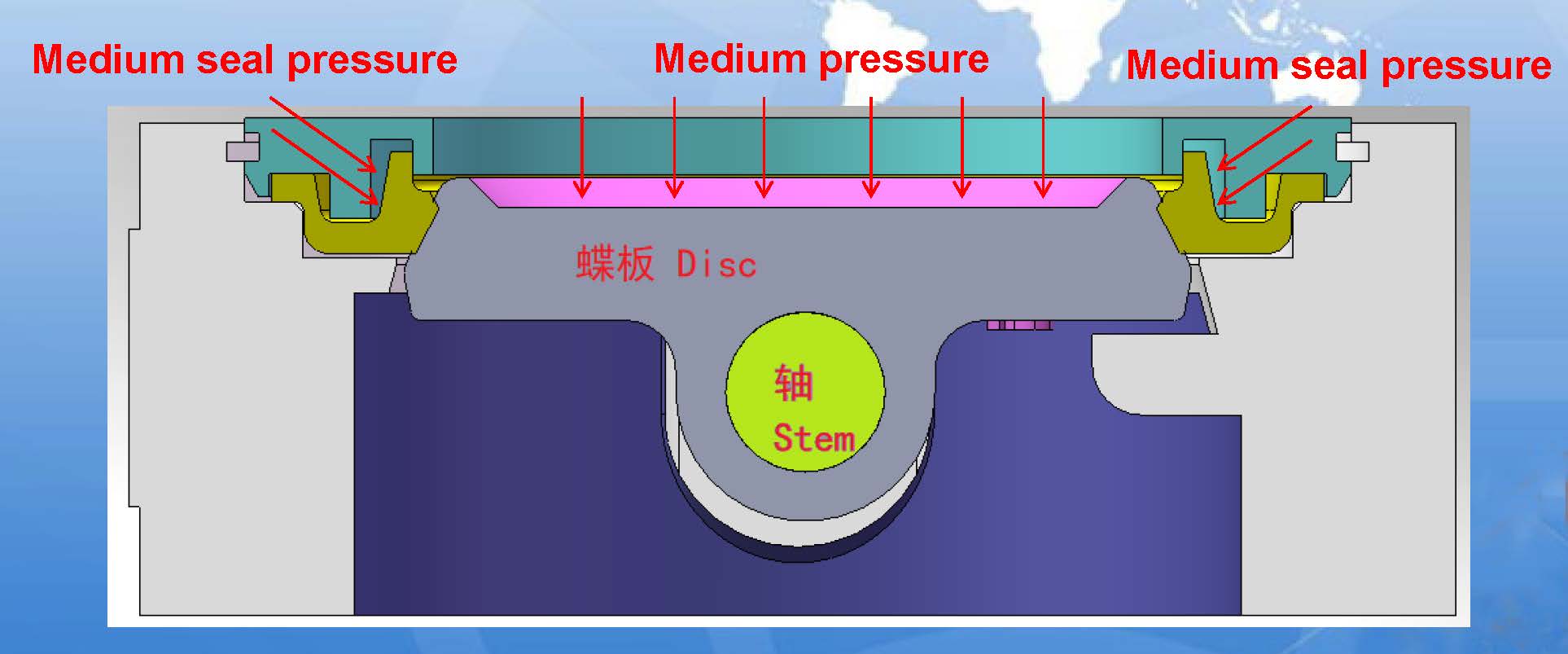

Stem-upstream Type

When the media flows from the back of the butterfly valve to the front, the butterfly plate is self-sealed due to the upward thrust of the media and the pressure of the seat

Stem-downstream Type

When the media flows from the front of the butterfly valve to the back, the medium generates thrust at the angle of the back of the seat and the butterfly plate forms a pressure self-sealing

Type of Operation for Double eccentric butterfly valve lug type

Technical specifications of Double eccentric butterfly valve lug type

| Design | API 609/ASME B16.34 |

| End Connection | Wafer/Lug/Double flanged |

| Operation | Manual/Pneumatic/Electric |

| Size Range | NPS 2"-60"(DN50-DN1500) |

| Pressure Rating | ASME Class150-300-600(PN16-PN25-PN40) |

| Body Material | Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel |

| Seat Material | PTFE, RPTFE, PPL |

| Temperature | -29℃ to 250℃ |

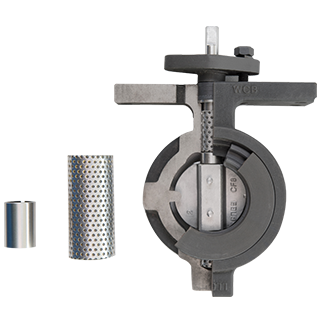

Product Show: Double eccentric butterfly valve lug type

What is the Double eccentric butterfly valve lug type used for?

High-performance Double eccentric butterfly valve lug type applications

3: High-pressure double-sided 6-stage sealing conditions: in condensate finishing system has a wide range of applications.

4: Oxygen operating conditions: This valve after degreasing treatment can be used for oxygen operating conditions, in parts

In terms of preparation, assembly, testing and packaging, the valve is cleaned in strict accordance with procedures.