API/API6d/API608 Cast/Stainless Steel Ss Float/Floating/Trunnion Type Industrial Gas/Oil/Water Electric/Pneumatic/Hydraulic 2/3 Pieces Full Bore/Port Ball Valve China factory

What's Electric trunnion ball valve ?

An Electric trunnion ball valve means that the ball is constrained by bearings and is only allowed to rotate, the majority of the hydraulic load is supported by the System constraints, resulting in low bearing pressure and no shaft fatigue.

The pipeline pressure drives the upstream seat against the stationary ball so that the line pressure forces the upstream seat onto the ball causing it to seal. The mechanical anchoring of the ball absorbs the thrust from the line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure operating torque remains low. This is particularly advantageous when the ball valve is actuated because it reduces the size of the actuator and hence the overall costs of the valve actuation package. The trunnion is available for all sizes and for all pressure classes but they are mainly for large sizes and high pressure conditions

Advantages of trunnion ball design is the lower operating torque, ease of operation, minimized seat wear (Stem/ball isolation prevents side loading and wear of downstream seats improving performance and service life), superior sealing performance at both high and low pressure (a separate spring mechanism and upstream line pressure is used as the sealing against the stationary ball for low pressure and high pressure applications).

Main features of NORTECH Electric trunnion ball valve

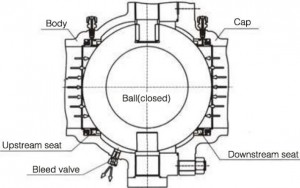

1.Double Block and Bleed(DBB)

When the valve is closed and the middle cavity is emptied through the discharge valve, the upstream and downstream seats will independently block. Another function of the discharge device is that the valve seat can be checked if there is a leakage during the test. In addition, the deposits inside the body can be washed through the discharge device.the discharge device is designed to reduce damage to the seat by impurities in the medium.

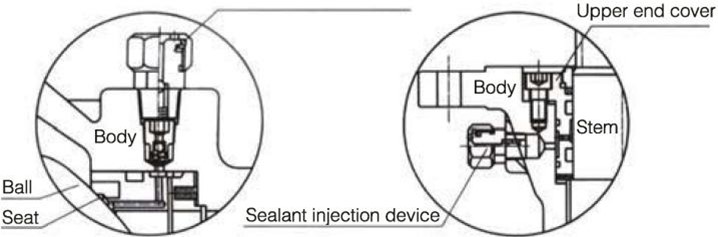

3.Emergency Sealing Device

The ball valves with the diameter more than or equal to 6'(DN150) are all designed with sealant injection device on stem and seat. When the seat ring or stem O ring is damaged due to accident, the corresponding sealant can be injected by the sealant injection device to avoid medium leakage on seat ring and stem. If necessary,the auxiliary sealing system can be used for washing and lubricating the seat to maintain its cleanliness.

Sealant Injection Device

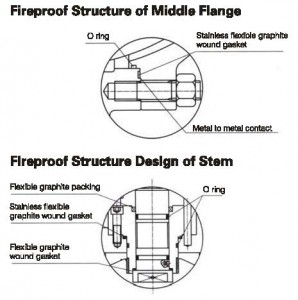

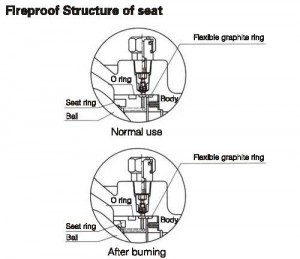

4.Fireproof Structure Design

In case of fire during the use of valve, the seat ring, stem O ring and middle flange O ring made of PTFE,rubber of other non-metal materials will be decomposed or damaged under high temperature.Under pressure of the medium, the ball valve will push the seat retainer rapidly towards the ball to make the metal seal ring contact the ball and form the auxiliary metal to metal sealing structure,which can effectively control valve leakage.The fireproof structure design of trunnion pipeline ball valve conforms to requirements in API 607,API 6FA,BS 6755 and other standards.

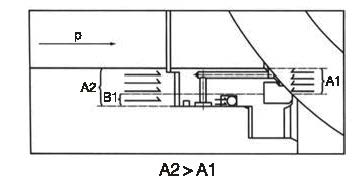

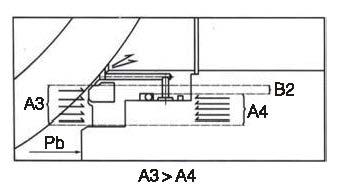

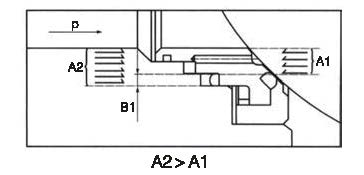

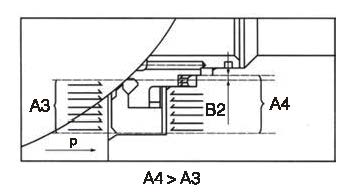

6.Reliable seat sealing structure

The seat sealing is realized through two floating seat retainers,They can float axially to block the fluid,including ball sealing and body sealing.The low pressure sealing of valve seat is realized by spring pre tightened.In addition, the piston effect of valve seat is designed properly,which realizes high pressure sealing by the pressure of the medium itself.The following two kinds of ball sealing can be realized.

The downstream side: Once the pressure “Pb” inside the valve Cavity increases, the force exerted on A3 is higher than that on A4. As A3-A4=B2, the pressure differential on B2 will overcome the spring force to make the seat released from the ball and realize pressure relief of valve cavity to the downstream part afterwards,the seat and ball will be sealed again under the spring action.

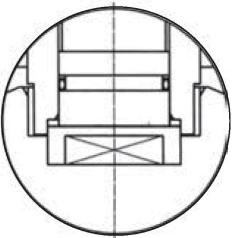

8.Double Sealing (Double piston)

The trunnion pipeline ball valve can be designed with the double Sealing structure before and after the ball for some special service conditions and user requirements. It has double piston effect. Under normal condition,the valve generally adopts primary sealing.When the primary seat sealing us damaged and causes leakage,the secondary seat can play the function of sealing and enhance the sealing reliability. the seat adopts the combined structure.The primary seal is metal to metal seal.The secondary seal is fluorine rubber O ring that can ensure the ball valve can reach the bubble level sealing. When the pressure differential is very low,the sealing seat will press the ball through the spring action to realize primary sealing. When the pressure differential rises,the sealing force of seat and body will increase accordingly so as to tightly seal the seat and ball and ensure good sealing performance.

Primary sealing: Upstream.

When the pressure differential is lower or there is no pressure differential, the floating seat will move axially along the valve under the spring action and pish the seat towards the ball to keep tight sealing. When the of valve seat is higher than the force exerted on the area A1,A2- A1=B1.Therefore,the force in B1 will push the seat towards the Ball and realize tight sealing of the upstream part.

Secondary sealing: Downstream.

When the pressure differential is lower or there is no pressure differential,the floating seat will move axially along the valve under the spring action and push the seat towards the ball to keep tight sealing. When the valve cavity pressure P increases,the force exerted on the area A4 of valve seat in higher than the force exerted on the area A3,A4- A3=B1.Therefore,the force on B1 will push the seat towards the ball and realize tight sealing of the upstream part.

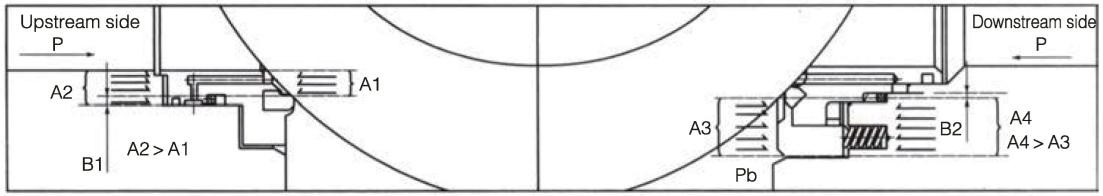

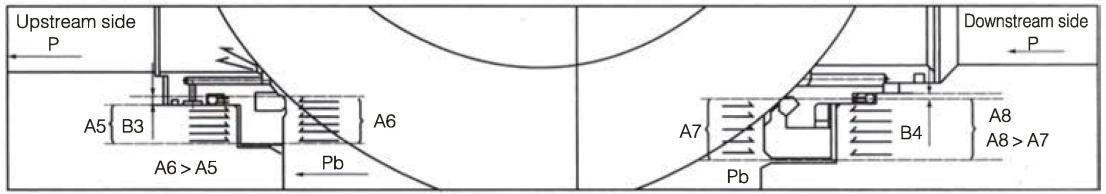

10.Special Structure of Automatic Pressure Relief Towards Upper Stream

As the ball valve is designed with the advanced primary and secondary sealing that has double piston effect,and the middle cavity cannot realize automatic pressure relief, he ball valve ith the special structure is recommended to meet the requirements of automatic pressure relief and ensure no pollution to the environment.In the structure,the upper stream adopts primary sealing and the lower stream adopts primary and secondary sealing When the ball valve is closed,the pressure in the valve cavity can realize automatic pressure relief to the upper stream,so as to avoid the danger caused by cavity pressure.When the primary seat is damaged and leaks,the secondary seat can also play the function of sealing.But special attention shall be paid to the flow direction of the ball valve.During the installation.Note the upstream and downstream directions.Refer to the following drawings for sealing principle of the valve with the special structure

Principle drawing of ball valve upstream and downstream sealing

Principle drawing of ball valve cavity pressure relief to the upper stream and down stream sealing

11.Blow-out Proof Stem

The stem adopts the blow-out proof structure.The stem is designed with the footstep at its bottom so that with the positioning of upper end cover and screw,the stem will not be blown out by the medium even in case of abnormal pressure rise in the valve cavity.

Blow-out Proof Stem

13.Extension Stem

As for the embedded valve,the extension stem can be supplied if ground operation is required.The extension stem is composed of stem, sealant injection valve,and drainage valve that can be extended to the top for the convenience of operation. Users should indicate the extension stem requirements and length when placing orders. For ball valve driven through electric,pneumatic and pneumatic – hydraulic actuators,the extension stem length should be from the center of pipeline to top flange.

Schematic diagram of extension stem

Specifications of NORTECH Electric trunnion ball valve

Trunnion Ball Valve Technical Specifications

• ISO 5211 mounting pad compatible for various type of actuators;

• simple structure,reliable sealing and easy maintenance.

• anti-static and fire safe design.

• ATEX certification for explosion proof.

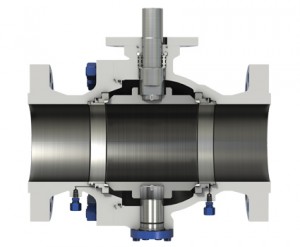

Product Show:

Application of NORTECH Electric trunnion ball valve

This kind of Electric trunnion ball valve is widely utilized in the exploiting, refining and transporting system of oil, gas and mineral. It can be also utilized to produce chemical products, medicine; production system of hydroelectricity, thermal power and nuclear power; draining system,