Rubber Disc Swing Check Valve

What is Rubber Disc Swing Check Valve ?

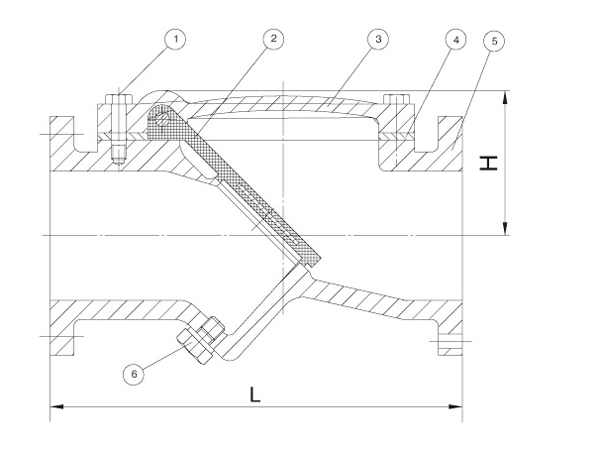

Rubber Disc Swing Check Valve consists of a valve body, a bonnet, and a disc that is connected to a hinge. The valve is of the swing check type utilizing an angled seat and fully encapsulated, resilient disc. It is capable of handling a wide range of fluids including flows containing suspended solids.The disk swings away from the valve-seat to allow flow in the forward direction, and returns to valve-seat when upstream flow is stopped, to prevent back flow. allows full, unobstructed flow and automatically closes as pressure decreases.These valves are fully closed when the flow reaches zero and prevent back flow.Turbulence and pressure drop within the valve are very low.The valve is opened by the fluid flow in one direction and closes automatically to prevent flow in the reverse direction.

The rubber disc swing check valve is mainly used for water supply and drainage system, and other industrial sectors of the pipeline outlet to prevent medium countercurrent. Because the sealing ring of the product is designed by inclined design, the closing time is short, and the water hammer pressure can be reduced. Rubber disc swing check valve disc is made of ductile iron with rubber vulcanized. It is erosion resistant and has good sealing performance. it has simple structure, easy maintenance, maintenance and transportation.

Main features of Rubber Disc Swing Check Valve

Features and benefits of the rubber disc swing check valves

- *Trouble-free operation and Efficiency and reliability through simplicity of design is the key to the superior performance and long life.

- *Angled disc and Non-Slam Closing Action

- *An optional lever arm and counterweight may be mounted to set the back flow of the fluid.

- *Non-Clog Design 100% flow area for improved flow characteristics and lower head loss,low pressure drop and reduced energy loss irrespective of pressure ratings.

- *Efficient and positive sealing under most flow and pressure conditions. Valve close before flow reversal.

- *Unrestricted flow area combined with smooth streamlined contouring allows passage of large solids minimizing the potential for clogging

Technical specifications of Rubber Disc Swing Check Valve

Technical specifications of the Rubber disc swing check valves

| Design and Manufacture | BS5153/DIN3202 F6/AWWA C508 |

| Face to face | EN558-1/ANSI B 16.10 |

| Pressure rating | PN10-16,Class125-150 |

| Nominal diameter | DN50-DN900,2″-36″ |

| Flange ends | EN1092-1 PN6/10/16,ASME B16.1 Cl125/ASME B16.5 Cl150 |

| Test and Inspection | API598/EN12266/ISO5208 |

| Options | lever arm and counterweight/with pneumatic actuator |

Product Show:

Application of rubber disc swing check valves

This kind of Rubber Disc Swing Check Valve is widely utilized in pipeline with liquid & other fluids.

- *HVAC/ATC

- *Water supply and treatment

- *Food and Beverage Industry

- *Sewage system

- *Pulp and Paper Industry

- *Industrial environmental protection