Fully Welded Ball Valve API6D CLASS 150~2500

What's full welded ball valve?

Nortech Full Welded Ball Valve is developed by the engineering technical personnel from the factory with more than 30 years experience in design and manufacture of high-pressure valve and international latest technical standard,it is mainly applied for the long distance pipeline transportation of petrol,natural gas and gas pipeline system in cities.Because of the special characteristics of underground type ball valve,the capability to endure pipeline stress, safety,weather resisting property and long run reliability is fully considered when designed.

Main features of full welded ball valve

1.lntegral Valve Structure

It is full welded by forged steel.The forging materials are subjected to ultrasonic examination according to ASME non-destructive examination(NDE) flaw detection requirements.The buttweld ending is subjected to particle penetration examination,RT services available.

2.Corrosion Resistance and sulfide Stress Resistance

Certain corrosion allowance is reserved for the body wall thickness,in consideration of corrosion.The carbon steel stem,fixed shaft,ball,seat and seat retainer ring are subjected to chemical nickel plating according to ASME B733 and B656.In addition,various corrosion resistant materials are available for users to select.According to customers’ request,the valve materials could meet the requirements of NACE MR 0175/1S0 15156 or NACE MR 0103,and strict quality control and quality inspection should be carried out during the manufacturing process so as to fully meet the requirements in the standards and meet the service conditions in sulfurization environment.

3.Integral Valve Structure

During the manufacturing process of the fully welded pipeline ball valve,the transition pipe can be welded for the welding ends valve.The transition pipe can be provided by users or by NORTECH,as per users request. Please indicate the transition pipe diameter and length A when placing orders.

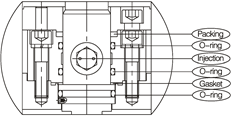

4. Stem Seal

To ensure good tightness,the 3 layers stem seal is designed to prevent leakage in different working conditions.

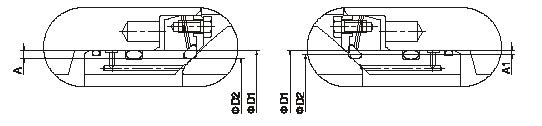

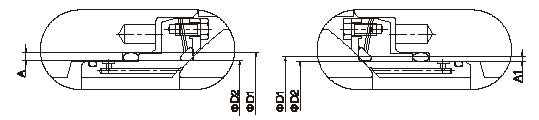

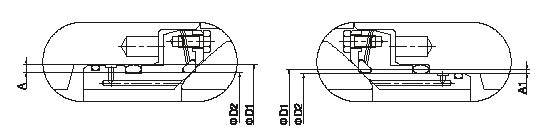

5. Seat structure

According to customer's request,the seat can be designed as DBB,DIB-1,DIB-2,to meet with requirements of different working conditions.

Seat DBB

Seat DIB-1

Seat DIB-2

Technical specification of full welded ball valve

Full welded ball valves

| Design and manufacturer | API6D |

| Body Material | Forged carbon steel,stainless steel,alloy steel |

| Nominal diameter | 6"-40"(DN150-DN1000) |

| End connection | BW,Flanged |

| Pressure rating | 150 - 1500 LB (PN16-PN320) |

| Operation | Lever,Gearbox,Electric,Pneumatic,Electro Hydraulic Actuator,Gas Over Oil Actuator. |

| Working temperature | -46℃-+200℃ |

Product Show:

What is the Fully Welded Ball Valves used for?

This kind of Fully Welded Ball Valves is widely utilized in petrol,oil,natural gas,gas pipeline and long-distance transport pipes.