Multi-turn Electric Actuator

What is Multi-turn Electric Actuator ?

Multi-turn Electric Actuator HEM series is a new generation of multi-turn electric actuators developed and manufactured by the technical team of NORTECH based on user needs and years of development experience.

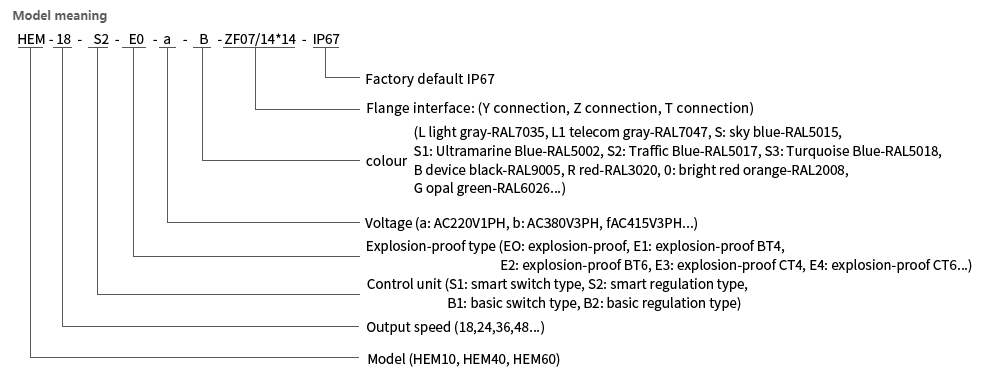

The HEM series can produce a variety of models according to user needs, such as basic, intelligent, bus, intelligent split and other forms, which are safe, stable and reliable to meet different application scenarios in various fields.

Main features of Multi-turn Electric Actuator

1. Reliability

The design of HEM series actuators has taken into account the application in the harshest occasions, and the parts used have been strictly inspected and tested to ensure the long-term reliability of the equipment. Based on years of design and manufacturing experience in the actuator industry, each actuator is inspected layer by layer before leaving the factory to ensure long-term and reliable operation of the actuator under different working conditions. The new generation of actuators has the most optimized control method; the enhanced signal processing method has complete shielding to the interference signal on the control signal; the electrical cavity is in the double-sealed waterproof housing, and the handheld infrared setter can be used. Set various parameters of the electric actuator, and all components meet the requirements of explosion-proof grade.

2. Simple debugging configuration

Debugging and software configuration are simpler and more user-friendly, with a newly designed man-machine interface, graphical menus are easy to understand, combined with corresponding operating instructions to make any parameter setting easier. Ensuring that the parameters are set correctly and maintaining their safety is the basis for stable operation. The configuration interface is more abundant, providing a variety of interface selection, configuration, diagnosis and other functions, using high-precision dot matrix LCD, which can easily switch between Chinese and English display, users do not need to remember many identification characters, just follow the prompts on the screen. Debugging is convenient to adapt to different operating environments.

3. Multiple control methods

The HEM series multi-turn actuators can provide a variety of extended control functions on the basis of the original switch type and adjustment type, including various industrial buses such as Modbus-RTU and Profibus-DP. Suitable for different control needs.

4. Perfect self-diagnosis and protection function

It can diagnose motor overload, overheating and power supply status. It can also automatically identify the phase of the three-phase power supply. There will be no reverse malfunction due to wiring changes. In an emergency, the actuator can be held in place or run to advance The set safety position; the actuator also has the ability to accurately measure the output torque, and protect the valve during operation to prevent the valve from being stuck; if the valve is stuck, when the start signal is sent, there will be no Any action, the logic circuit can disconnect the motor to prevent the motor from overheating and send out an alarm signal;

Technical specification of Multi-turn Electric Actuator

Product Application: part turn electric actuator

Multi-turn Electric Actuator is mainly used to control valves and constitute electric valves. It can be installed with globe valve, gate valves, etc,and large size ball valve,butterfly valves,plug valves,with part turn gearbox to reduce the torque value,using electricity instead of traditional manpower to control valve rotation to control air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. Fluid flow and direction