Electrical Butterfly valve manufacturer china DN50 DN1200 High Quality with WRAS certified

What is Electrical Butterfly Valve ?

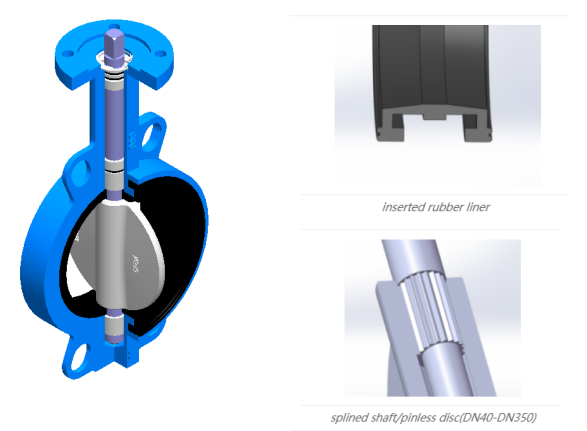

Butterfly Valve,is also referred to as “concentric”,"rubber lined" and “rubber seated” butterfly valve,has a rubber (or resilient) seat between the external diameter of the disc and the internal wall of the valve.

Butterfly valve is a quarter-turn valve that rotates 90 degrees to open or close the media flow. It has a circular disc, also known as the butterfly, found at the center of the body that functions as the closing mechanism of the valve. The disc is connected to an actuator or handle through the shaft, which goes through from the disc to the top of the valve body.

The movement of the disc will determine the position of the butterfly valve.The resilient seated butterfly valve wafer type can work as isolating valve if the disc rotates a full 90-degree turn, the valve is completely opened or closed.

Electrical Butterfly Valve ,the most compact design with short face to face.it's fit between two flanges,with studs passing from one flange through other. The valve is held in place and sealed with gasket by the tension of studs.A resilient seated butterfly valve wafer type is a lightweight, maintenance-free, cost-effective, and reliable solution to various applications.

Main Features of NORTECH Electrical butterfly valve wafer type

WHY TO CHOOSE US?

- Quality and service:more than 20 years of experiences of OEM/ODM services for leading european valve companies.

- Quick delivery,ready for shipment 1-4 weeks,with considerate stock of resilient seated butterfly valves and components

- Quality guarantee 12- 24 months for resilient seated butterfly valves

- Quality control for each piece of butterfly valve

Main features of Electrical butterfly valves

- Compact construction results in low weight, less space in storage and installation.

- Centric shaft position,100% bi-directional bubble tightness,which makes installation acceptable at any direction.

- Full bore body gives low resistance to flow.

- No cavities in the flow passage,which makes it easy to clean and disinfect for potable water system etc.

|

NORTECH Resilient seated butterfly valve pinless design |

|

please refer to our catalogue of butterfly valves for details or contact our sales team directly.

Types of Operation for Electrical butterfly valves

| Handle lever |

|

| Manual gearbox |

|

| Pneumatic actautor |

|

| Electric actuator |

|

| Free stem ISO5211 mouting pad |

|

Technical specification of Electrical butterfly valves

Standards:

| Design and Manufacturer | API609/EN593 |

| Face to face | ISO5752/EN558-1 series 20 |

| Flange end | ISO1092 PN6/PN10/PN16/PN25,ANSI B16.1/ANSI B 16.5 125/150 |

| Pressure rating | PN6/PN6/PN16/PN25,ANSI Class125/150 |

| Test and Inspection | API598/EN12266/ISO5208 |

| Actuator mounting pad | ISO5211 |

Main parts materials of Electrical butterfly valve :

| Parts | Materials |

| Body | Ductile iron,carbon steel,stainless steel,duplex stainless steel,Monel,Alu-bronze |

| Disc | Ductile iron nickel coated,ductile iron nylon coated/Alu-bronze/stainless steel/duplex/Monel/Hasterlloy |

| Liner | EPDM/NBR/FPM/PTFE/Hypalon |

| Stem | Stainless steel/Monel/Duplex |

| Bushing | PTFE |

| Bolts | Stainless steel |

Valve body materials of Electrical butterfly valves

| Ductile iron |

|

|

| Stainless steel |

|

|

| Alu-bronze |

|

|

Valve disc materials of Electrical butterfly valve

| Ductile iron nickel coated |

|

|

| Ductile iron nylon coated |

|

|

| Ductile iron PTFE lined |

|

|

| Stainless steel |

|

|

| Duplex stainless steel |

|

|

| Alu-bronze |

|

|

| Hasterlloy-C |

|

|

Rubber sleeve liner of Electrical butterfly valve

| NBR | 0°C~90°C | Aliphatic hydrocarbons(fuels,low aromatic containing oils,gasses),sea water,compressed air,powders,granular,vacuum,gas supply |

| EPDM | -20°C~110°C | Water in general(hot-,cold-,sea-,ozone-,swimming-,industrial-, etc).Weak acids,weak salt solutions,alcohols,ketones,sour gasses,sugar juice |

| Sanitary EPDM | -10°C~100°C | Potable water, foodstuffs, unchlorined drinking water |

| EPDM-H | -20°C~150°C | HVAC, chilled water, food stuffs & sugar juice |

| Viton | 0°C~200°C | Many aliphatic, aromatic and halogen hydrocarbons, hot gasses, hot water, steam, inorganic acid, alkali |